Sizing, Quality, and Seasonal Insights

For any global seafood importer, Penaeus vannamei—commonly known as Whiteleg Shrimp—is a cornerstone of the modern seafood portfolio. Its versatility, mild flavor, and excellent texture have made it the most cultivated shrimp species worldwide.

India has firmly established itself as a leading producer and exporter of Vannamei shrimp, recognized for its scale, technological advancement, and commitment to quality in aquaculture. However, to build a reliable and profitable supply chain, importers must look beyond pricing alone. A deep understanding of shrimp quality indicators, sizing classifications, and seasonal availability is essential.

This guide presents actionable insights from the field, enabling importers to make informed, strategic sourcing decisions.

Understanding True Quality: Beyond Technical Specifications

While most suppliers provide standard specification sheets, only experienced exporters deliver quality that meets international benchmarks consistently. Here are the key indicators that should guide your selection:

Texture and Firmness: High-quality Vannamei shrimp should have a firm, crisp texture when thawed. It should feel solid and exhibit a slight spring-back effect. A soft or mushy texture can indicate poor feed quality, delayed freezing, or harvesting practices that allowed enzymatic degradation to begin.

Color and Appearance: Raw Vannamei shrimp should appear translucent and grayish-white. There should be no signs of melanosis (black spot), which often appears as dark patches on the shell or flesh. While sodium metabisulfite is commonly used to delay melanosis, superior suppliers focus on rapid handling and quick freezing to preserve natural freshness without overuse of additives.

Odor Profile: Thawed shrimp should emit a mild, clean, ocean-like smell. Any ammonia-like or pungent fishy odor is a sign of decomposition and indicates unacceptable quality.

Glazing and Processing Integrity: A glaze layer protects the product from dehydration and freezer burn during storage. A responsible supplier maintains glazing levels between 8 to 12 percent. Some suppliers may inflate glazing (20 to 30 percent) to reduce costs, effectively selling water weight. Reputable exporters clearly disclose net versus gross weights and ensure uniform, protective glazing.

Sizing Explained: The Count System in Shrimp Sourcing

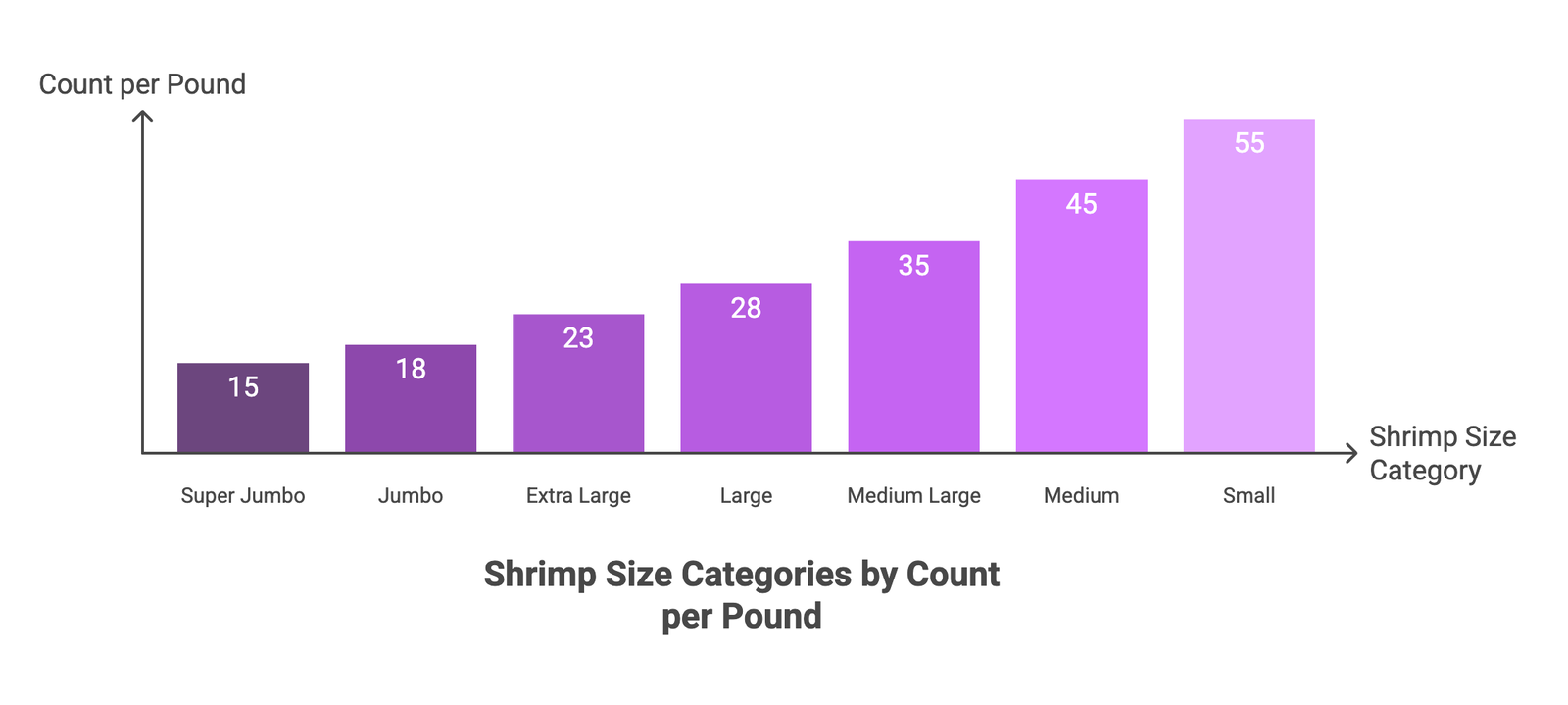

Shrimp sizing is based on the number of shrimp per pound, known as the “count.” Lower count numbers indicate larger shrimp.

Typical Headless Shell-On (HLSO) Sizing Chart:

Minimize imageEdit imageDelete image

Key Consideration: Sizing standards differ based on the product form. For example, the count for Headless Shell-On (HLSO) shrimp will differ from that of Peeled and Deveined (PD) shrimp from the same harvest. Always confirm sizing specifications according to the product form.

Common Product Forms:

- HOSO – Head-On Shell-On

- HLSO – Headless Shell-On

- PD – Peeled and Deveined

- PUD – Peeled and Undeveined

- PDTO – Peeled, Deveined, Tail-On

A professional supplier will provide clear sizing and packaging specifications for each form.

Seasonal Planning: Aligning with Indiaʼs Harvest Cycles

India follows two major farming seasons for Vannamei shrimp. Aligning procurement plans with these cycles allows importers to optimize both quality and cost.

Main Harvest (Winter Crop): August to November

- Supply Availability: Peak season with high volumes across all sizes

- Product Quality: Ideal environmental conditions support robust, healthy growth

- Pricing Advantage: Prices are typically lowest due to high market supply

- Procurement Strategy: Ideal time for bulk purchasing and long-term contracts

Secondary Harvest (Summer Crop):

February to May

- Supply Availability: Strong, though slightly more variable

- Product Quality: Generally good, but higher temperatures may affect size distribution

- Pricing Trend: Moderate pricing due to balanced global demand

- Procurement Strategy: Plan for medium volumes and staggered shipments

Transitional Periods (December–January and June–July)

These months mark the transition between farming cycles. Fresh harvests are minimal. During this time, reliable exporters draw from frozen inventory built during the peak season.

- Stock Dependency: Buyers should plan inventory in advance and work with suppliers capable of maintaining frozen stocks

- Risk Mitigation: Secure supply agreements prior to low-landing periods to ensure business continuity

Building Long-Term Value through Strategic Partnerships

The Vannamei shrimp trade is highly competitive, but consistent profitability lies in building reliable, transparent relationships with exporters who prioritize quality and integrity.

- What defines a strategic sourcing partner?

- Strong track record of quality control

- Transparent communication on weights, sizing, and pricing

- Consistent product availability across all seasons

- Capacity to meet large-volume demands

- Willingness to collaborate on forward planning and logistics

A great supplier is more than a vendor. They act as your eyes and ears on the ground, ensuring that quality is maintained from pond to port. By aligning your sourcing strategy with clear benchmarks of quality, accurate sizing, and seasonal cycles, you can create a sustainable and high-margin supply chain.